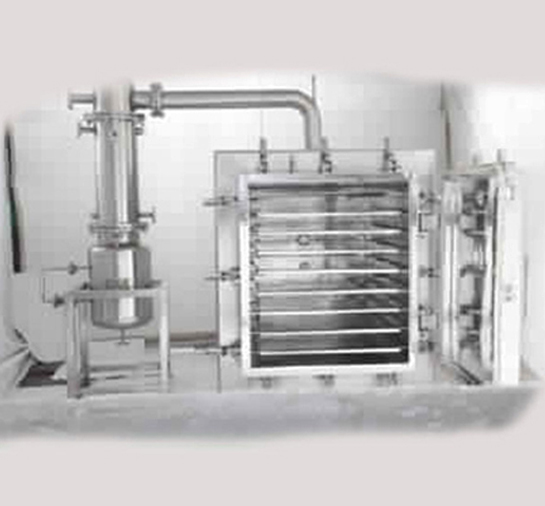

VACUUM TRAY DRYER MANUFACTURER & SUPPLIER

WORKING PRINCIPLE :

Vacuum Tray Dryer (VTD) is an important laboratory equipment used for drying high grade oxygen and temperature sensitive materials. Inside the dryer are several shelves having trays in which products are Placed. They are specifically designed to dry products which contains moisture . every shelf has inlet and outlet Nozzle. The shelves are constructed hollow with baffles placed between shelves.The hot medium flows like zigzag into shelves .vaccum is applied to condensate receiver. vapour evolved during drying process collects in the receiver , after it is cooled in heat exchanger vacuum tray dryers are advanced heat transfer system that ensures uniform distribution of heat between the plates and the sample. The sample is sterilized at a high pressure prior to the drying process so as to eliminate any form of microorganisms or contaminants present in them. On successful sterilization, the sample gets dried at a temperature range of 700C to 1150C for a pre-set period of time

SALIENT FEATURES :

• Main Body made up From SS 304 / SS 316 / SS 316L Graded GMP Models• Shelves SS 316 Pads with Flow Baffles

• Silicon gasket at the door for 100% soundproofing and weatherproofing

• Receiver and Condenser in either SS 304 or SS 316

• Shelves Movable System on External Trolley

• Trays Made of SS 304 / SS 316

• The External body is made up of heavy duty stainless steel (SS) grade 304 / 316 / 316 L grade

• The inner chamber is made from durable, moisture resistant

• The trays have mirror finish and come with curved edges for safety purpose

• Advanced digital temperature control system backed by solenoid pneumatic valve for hot water inlet

• User-friendly digital panel, indicating the pressure, temperature and overall time for operation

• Drain valve and vacuum break valve fixed at the vacuum chamber to achieve desired setting.

APPLICATION :

• Food processing industries• Chemical industries

• Pharmaceutical industries

• Powder industries

• Plastic manufacturing industries

• Paper industries